For Sales / Support Call / Email:

+91 20 26930908 / 26930960 / 61 Sales@steamequipments.com

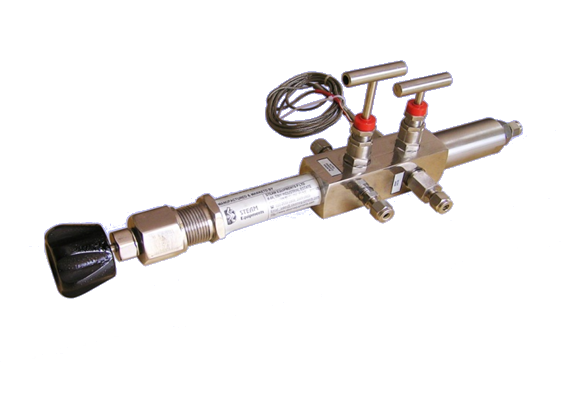

Variable Pressure Reducer with Thermal Safety valve

The Variable Pressure Reducer with Thermal Safety valve (VRTS) is used to reduce the pressure and control the flow of high-pressure steam and liquid samples, and shut off the sample line for high sample temperature. The VRTS is a compact version for pressure reduction. The pressure of the incoming sample is reduced as the liquid is forced to travel through the narrow gap between the tapered rod and the rod opening. Because the work is done over the entire length of the rod, localized wear is held to a minimum. The result is a very long service life compared with devices in which the pressure drop is taken over a very short distance (fixed orifice, pressure regulator, etc.). Other devices erode frequently causing function loss and down time. Thermal shut off valve at the end will close if sample temperature increases by preset value. These type of pressure reducers are recommended by ASME 19.11-1997.

• Wetted Material: Stainless Steel 316

• Pressure rating: 5680 psig (400 bar(g))

• Temperature rating: 650 °C

• Maximum Flow: 100 LPH (liquid)

• End connections: ¼” (6.4 mm) OD tube

• Maintenance free with online clearing arrangement.

• Robust design.

• In line with recommendations of ASME PTC 19.11-2008.

• No Filters Required.

Use to reduce sample pressure in following applications.

• Steam & Water Analysis Systems

• Boiler water Blowdown systems

• Grab Sampling systems, etc

© 2020. Steam Equipments Pvt Ltd. All Rights Reserved.