For Sales / Support Call / Email:

+91 20 26930908 / 26930960 / 61 Sales@steamequipments.com

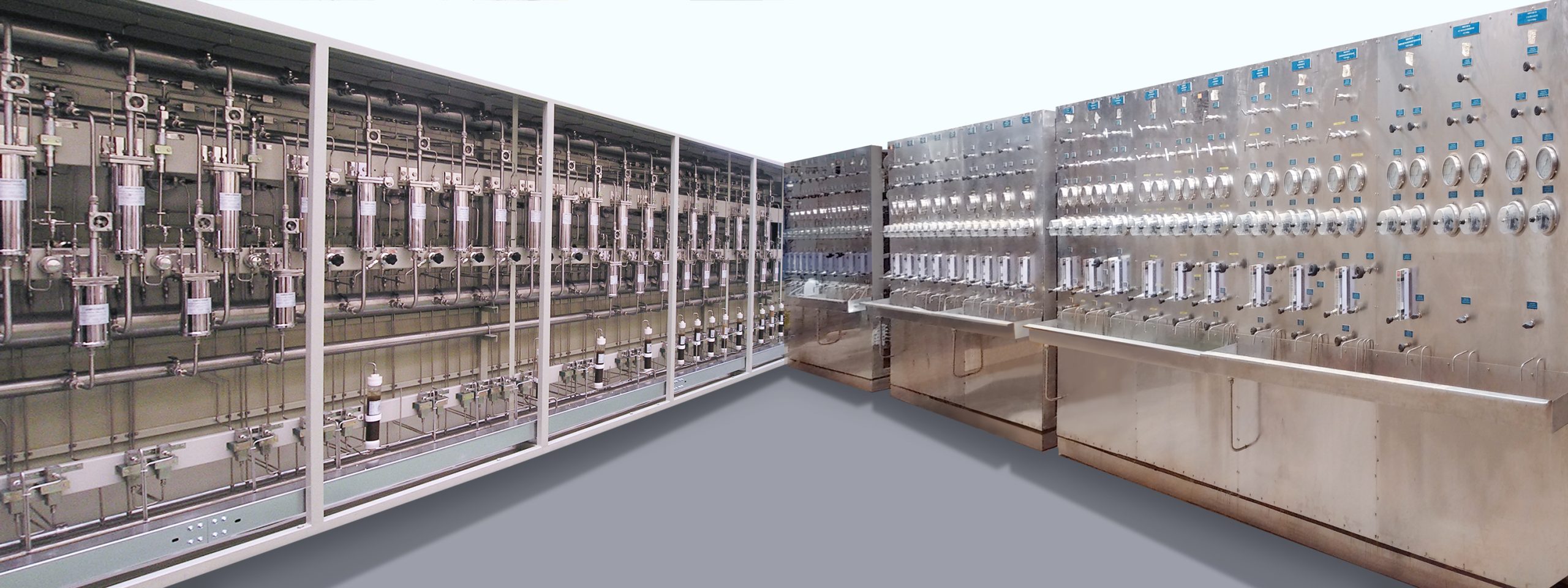

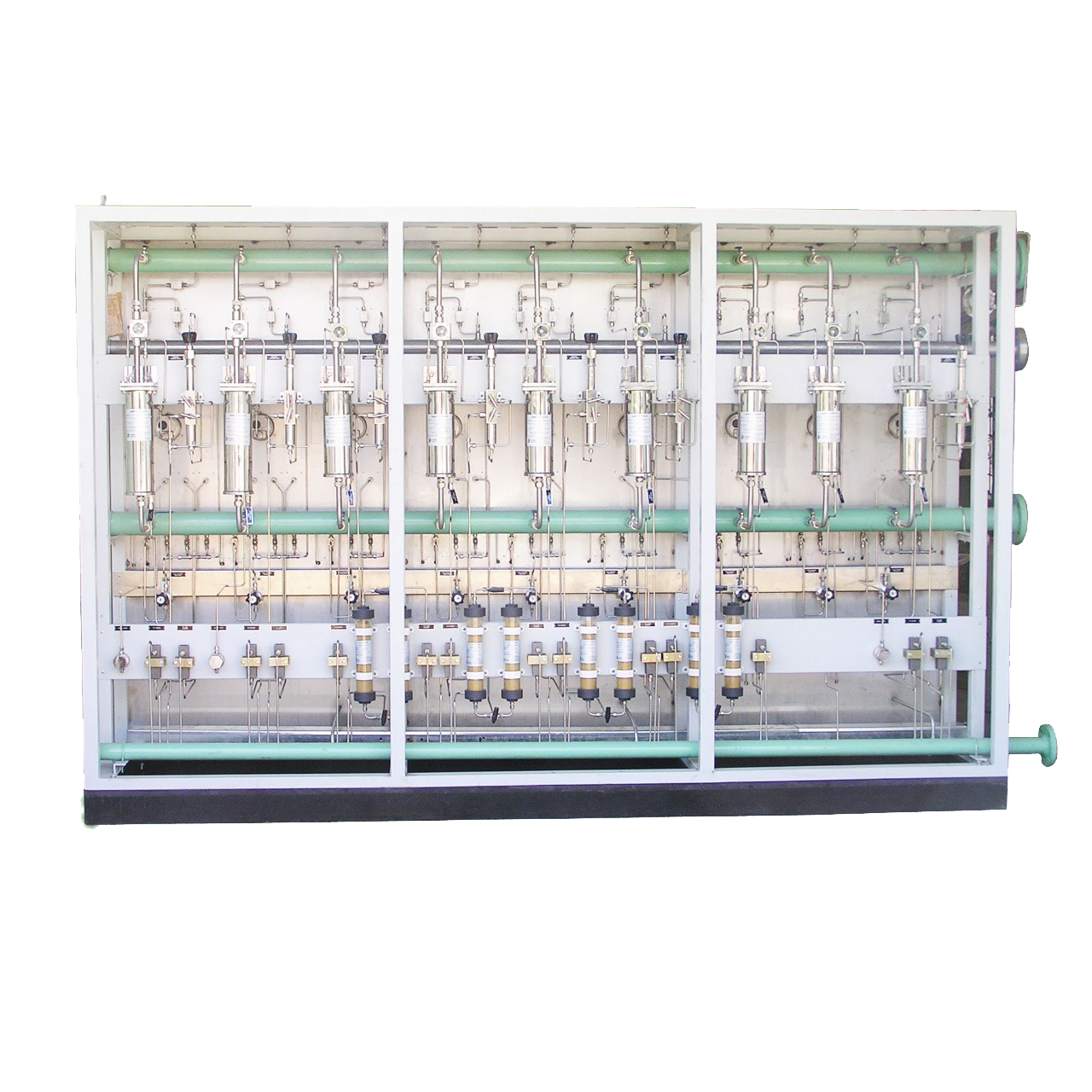

Modular System

Modular Sampling Systems (custom built)

Modular sampling panels for primary sampling and secondary sampling; Primary sampling module includes inlet isolation valve, blow down valve, sample cooler with cooling water inlet and outlet valve with coolant flow indicator to diagnose required flow of cooling water. Pressure reduction and high sample temperature safety valve (thermal shut off valve).

Primary cooling sampling panel consists of rotameter, Back Pressure Regulator, Pressure Gauge, Temperature Gauge and Grab Valve with Tundish.

For conditioning scheme of both, primary and secondary panel- secondary panel includes Secondary Sample Cooler with chilled water inlet and outlet valve with chilled water Flow Indicator, Rotameter, Back Pressure Regulator, Pressure Gauge, Temperature Gauge and Grab Valve with Tundish. The chiller unit is skid mounted modular type, it’s a separate unit which will be connected to secondary cooler chilled water inlet and outlet connections.

All Systems are designed in compliance with ASME PTC-19.11, USA, GDCD, UK, EPRI, VGB Standard S006-2012

• Designed as per ASME PTC 19.11 recommendations.

• Design temperature of 650oC and pressure of 400 Bar.

• Compact double helix type, shell and tube sample coolers.

• All high-pressure components to pressure reducer can withstand temp up to 550oC.

• Automatic high temp shut off valves are used for high temp protection.

• No power supply required.

• No wiring required.

• Rod in tube type pressure reducer.

• Online pressure regulator cleaning.

• Back pressure regulator with SS diaphragm.

• Easy access to components.

• SS cooling water pipeline.

• Low maintenance Required

• Cost Effective system

• Accurate & stable measurement system

• Long Life Equipments

• Compact design

• Steam applications Feed water

• Condensate, Boiler Water

• LP Drum Water

• LP/HP Steam, Life Steam

• Main Steam Demi Water

• Condensate, Boiler Water

• LP Drum Water

• LP/HP Steam

• Main Steam for power stations

© 2020. Steam Equipments Pvt Ltd. All Rights Reserved.