For Sales / Support Call / Email:

+91 20 26930908 / 26930960 / 61 Sales@steamequipments.com

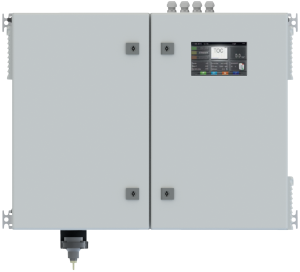

Total Organic Carbon Analyzer

Measuring TOC continuously online is the perfect solution for monitoring contamination and discharges. The TOC Analyzer measures total organic carbon in liquid samples using the method of UV persulfate oxidation with subsequent carbon dioxide detection by nondispersive infrared absorption (NDIR). The analyzer can measure TOC in liquid samples ranging from 0–5 mg/L to 20,000 mg/L. The method conforms to DIN, CE, ASTM regulations.

The sample first is acidified and then sparged to remove inorganic carbon. The remaining liquid is mixed with sodium Persulfate and digested by two high-performance reactors. The resulting CO2 is then stripped from the liquid and, after drying, its concentration is measured by a NDIR analyzer.

• Dual compartment enclosure for liquid and electronics

• Auto-cleaning functions as standard

• Auto-calibration or auto-validation functions as standard

• Integral air compressor option eliminates carrier gas requirement

• Ethernet option is available

• Integral data-logger with USB port for download

Measuring principle/Technology | UV-promoted persulfate oxidation(TOC) nondispersive infrared(NDIR) -(TC) |

Measuring Range | 0–5 mg/L to 20,000 mg/L (Range as per requirement) |

Lower Detection Limit (LDL) | 0.2 mg/L |

Accuracy | ± 2% of full scale nondiluted, ± 4% of full scale diluted ranges |

Response Time | T90<From 6 minutes, depending on range |

Operating temperature | Ambient: 5-40°C / 41 – 104°F Sample: 2° to 70°C/36° to 158°F |

Operating Humidity | 0 – 90% relative humidity, non-condensing |

Power supply | 110 or 230 VAC 50/60 Hz |

Analog output | 4–20 mA |

Digital Output | RS-485 MODBUS-RTU (standard), optional Ethernet |

Power Consumption | 350 VA (115 VAC), 250 VA (230 VAC) |

Display | 7-inch Touchscreen Color LCD |

Relay | 2 SPDT contacts for online, offline, loss of sample, result alarm, validation alarm, reagent alarm, calibration alarm & instrument fault alarm |

Required sample temperature | 2–70°C / 36 – 158°F |

Required sample Pressure | Pressure less from overflow vessel (Fast Loop Reservoir) |

Reagent | Phosphoric acid and sodium persulfate |

Reagent Consumptions | approximately 10 L/month for continuous operation |

Utilities | Air or Nitrogen, CO2 free (optional integral air compressor) |

Enclosure Material |

|

IP Rating | IP65/NEMA 4 |

Auto clean, auto calibration, auto validation functions | Available using peristaltic pump |

Mounting | panel/wall installation |

Overall Dimension | 760 × 600 × 210 mm / 29.9 x 23.6 x 8.3 in |

Weight | 37 kg |

Certificate conformity | EN 610004-2, EN 610004-4, C 46-022, EN 55022, EN 61326(electromagnetic compatibility) |

© 2020. Steam Equipments Pvt Ltd. All Rights Reserved.